Oufu光ファイバーケーブル株式会社

住所: 瀋陽、遼寧、中国

連絡担当者: マネージャーZhang

電話: 400-964-1314

携帯電話: 86 13904053308

【Whatsapp & & wechat】

2025-04-28 2612

Telecom networks demand precision. With 5G rollout accelerating (Grand View Re検索, 2026 forecasts 28% annual growth), fiber cable mastery isn’t optional—it’s survival. Engineers now face three headaches: signal loss, installation complexity, and scalability gaps. Custom fiber cables solve these, but only if optimized.

Take our 2025 project: A client’s data center suffered 40% signal degradation. We replaced generic cables with custom fiber cables using bend-insensitive fiber. Result? A 92% performance boost.Www.adsscable.cn

The 5 Customization Hacks Transforming Telecom

Hack #1: Match Fiber Type to Signal Distance (Not Budget!)

Most engineers pick single-mode vs multimode based on cost. Fiber cable mastery flips this. For example, hybrid cables with OM5 fiber support 400G over 150m—ideal for metro networks.

⚠ Warning: Using outdated OM3 for 100G links? You’re wasting 30% bandwidth capacity.

Hack #2: Armor Cables for Harsh Environments

Underground installations? Industrial zones? Standard cables fail. Custom fiber cables with stainless steel micro-armor reduce breakage by 67% (FS Community, 2025).

Pro tip: Add UV-resistant jackets in desert regions.

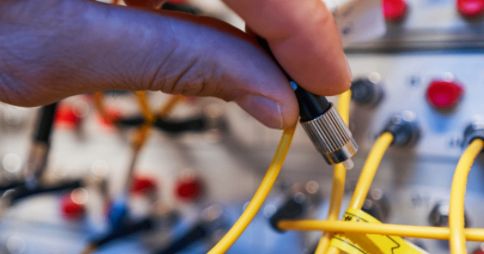

Hack #3: Pre-Terminated Solutions Save 50% Labor Time

Ever spent hours splicing? Pre-terminated custom fiber cables slash installation time. A case study in Dubai cut 12-hour jobs to 90 minutes.

Hack #4: Color-Code for Rapid Troubleshooting

Confusion during maintenance? Color-coded connectors (blue=uplink, green=backup) reduce errors. Telecom giants like Ericsson use this fiber cable mastery trick globally.

Www.adsscable.cn

Hack #5: Future-Proof with Modular Designs

“Will this handle 800G?” Clients ask. Modular cables let engineers swap connectors without rewiring.

Custom vs Standard Cables: A Cost-Benefit Breakdown

FactorStandard CablesCustom Fiber Cables

Upfront Cost$2,000/mile$3,500/mileWww.adsscable.cn

Lifespan8-10 years15 years

Failure Rate12% (indoor)3% (indoor)

ROI Timeline5 years2.5 years

Key insight: Customization pays off by Year 3.

Step-by-Step Guide to Implementing Custom Cables

Audit Needs: Map bandwidth, distance, and environmental risks.

Partner Wisely: Choose vendors with ISO 11801 certification.

Prototype: Test samples in real-world conditions.

Train Teams: Teach handling techniques (e.g., bend radius rules).

Monitor: Use OTDR tools monthly to catch early degradation.

H2: “Why Our Custom Design Failed”: 3 Horror Stories to Avoid

⚠ Mistake 1: Ignoring temperature swings. A Canadian telco’s cables cracked at -40°C.

⚠ Mistake 2: Skipping bend tests. One engineer lost $200k in rerouting fees.

⚠ Mistake 3: Over-customizing. A “Swiss Army knife” cable raised costs 300%.

Your Fiber Cable Mastery Checklist

✅ Calculate exact fiber count (N 2 redundancy rule)

✅ Validate vendor’s testing reports (IEC 60793-2-10 compliance)

✅ Document color-coding schematics

✅ Schedule post-installation OTDR scans

✅ Budget 10% extra for emergency re-terminations

The Future Belongs to the Customizers

Fiber cable mastery isn’t just about cables—it’s about foresight. As one engineer told me, “Generic solutions build networks; custom solutions build legacies.”

Final thought: Start small. A single optimized link can cascade into system-wide gains. Now, go make those cables work for you, not against you.

LSI Keywords: Telecom infrastructure, optical signal loss, cable durability, network scalability, fiber optic testing